… requires an equal

in metal cleaning

Demands are high and frustrations even more so. Keeping impeccable level of cleanliness for the next step in the production process. Increasing cost pressures from your CFO. Demands for reducing your environmental footprint from HSE.

It seems like an endless list. Never has the importance of optimizing parts cleaning processes for you as an OEM and for your suppliers been more vital.

We are ready to help you with the best industrial cleaners and degreasers and cut cost on your energy bill without compromising on cleanliness.

How about these numbers?

3 X

Bath life time

increase

59 %

Energy

cost savings

56 %

Waste-water

cost reduction

37 %

Man hour

cost reduction

Without compromising on cleanliness. Obviously.

Would you also like an industrial cleaner that helps you save money due to low temperature and long bath life times?

Pure Performance

for high performance

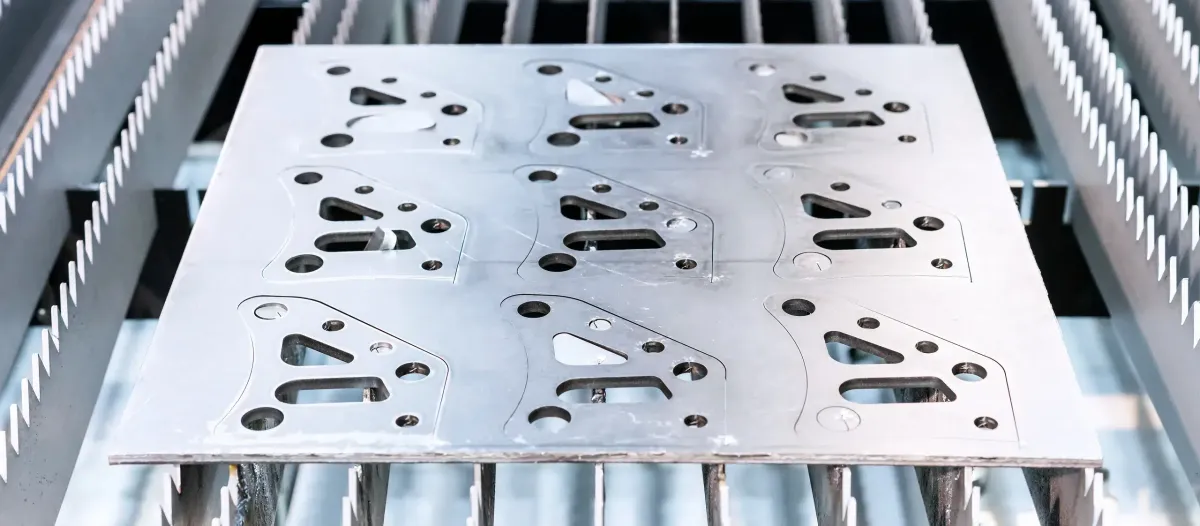

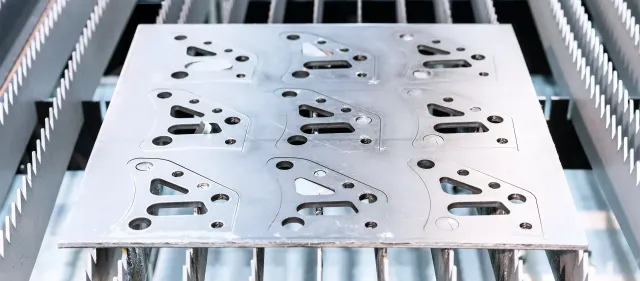

It is cleaning-critical to provide the right blend of chemistry to remove contaminants and prepare the part for the next step in your process. That is why we assess your requirements and test a wide range of industrial cleaners in relation to your current application and equipment available, before suggesting which water-based cleaning solution you should choose.

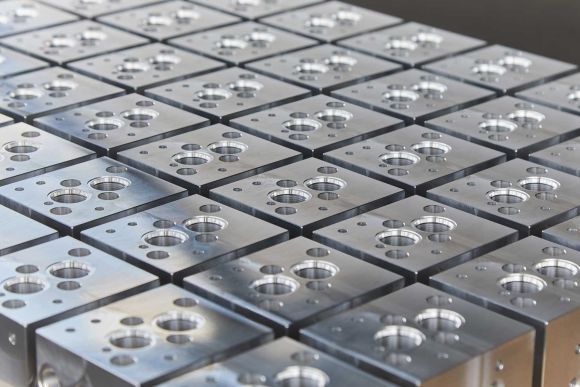

Choose the best industrial degreaser

You are producing high precision components, and as a result the machined parts are increasingly sensitive to contamination. In our lab in Denmark, we develop and produce industrial cleaners and degreasers that help you clean for the next step in your manufacturing process. No matter if you need to paint, weld, assemble, machine or ship, we’ve got your back.

Maintenance

and service

We are in this together.

Since 1987 we have helped customers clean parts and since then, maintenance and service have played a vital role in our concept. We just can’t leave you alone in this crucial part of your process. We stick to our promise by providing maintenance and service, making sure that your requirements are met – every day.

From one expert to another.

Service includes:

- Regular visits

- Optimisation

- Check-up on baths

- pH measurements

- Temperature regulation

- Test of oil-skimmer

Maintenance

and service

We are in this together.

Since 1987 we have helped customers clean parts and since then, maintenance and service have played a vital role in our concept. We just can’t leave you alone in this crucial part of your process. We stick to our promise by providing maintenance and service, making sure that your requirements are met – every day.

From one expert to another.

Service includes:

- Regular visits

- Optimisation

- Check-up on baths

- pH measurements

- Temperature regulation

- Test of oil-skimmer

Leave a positive impact with enviro-friendly industrial soaps

All our products are formulated to improve cleanliness, with less impact on the environment and to help create a safer work environment. That allows you to reduce waste and pollution, and support a more sustainable production. At the same time, you cut cost on energy and, cut cost on longer bath life times, which leaves you with more time for production. Simple right?

If you like many other companies are eager to minimise that carbon footprint, DST-DEGREEZ is an important step in this direction.

Metal cleaning

is what we do

We have helped manufacturing companies and their suppliers clean and degrease machined parts since 1987. Over the years, we have adapted our product line to meet the cleaning needs of our customers. As a result, we can help improve cleanliness on any kind of metal. This includes:

- Aluminium

- Brass

- Copper

- Zinc

- Steel

- Cast iron

- Stainless steel

See how others do

We’ve done it before. Actually, we have helped professionals like you since 1987.

Both ZF Wind Power and Danfoss are prime examples of this.