Enhanced effectiveness

in complicated parts cleaning

Let’s introduce our latest addition to the DST-product portfolio. A new line of products consisting of high viscosity ready-to-use gels that have been meticulously developed to accommodate oversized or complicated components, ensuring they receive the attention they deserve.

Follow these simple steps:

- Spray on parts

- Leave for a few minutes

- Rinse off.

Discover the convenience and effectiveness of this innovative pink product as you streamline your operations with a non-hazardous, practical, and cost-effective gel.

On top of that, it’s tough on all types of contamination, from sticky oils to brake dust.

3 reasons customers choose DST-GEL

Time-saving

The exceptional cleaning performance from this high viscosity gel let’s you effectively remove sticky passivation oils, burnt-on oils and grease, tar, brake dust, small metal parts from wheels and tracks.

Peace of mind

The gels are non-labelled which means hassle-free usage . You don’t have to worry about work place safety compliance.

Cost effective

The visual clarity of the gels means that you can easily keep track of the areas cleaned. This both makes it easier for the operator using the gel to see what and where has been clean which translate into less product consumption.

The smart choice for urban maintenance

Considering investing in a costly train washing system? But don’t really have the space for it?

Before you commit to a pricey setup, consider a smarter alternative: gel-based cleaning solutions.

With significant cost savings and an efficient cleaning power, DST-GEL might just be the smarter choice.

Don’t worry about spatial constraints or operational hassles. This gel optimizes your time and effort while delivering superior cleanliness.

Oversized industrial cleaning made simple. Made adaptable. Made visible.

Safety first.

For you and the environment

We understand the constraints of the workplace. That’s why DST-GEL requires no labeling. It’s hassle-free and complies with safety regulations, ensuring peace of mind during use.

And when you’re done? Disposal is just as easy. The mobile gel loses its viscosity when rinsed, making it ready for safe disposal in wastewater treatment plants or water separators.

And did we mention that with its visual clarity, you see exactly where you’ve applied the product, ensuring no spot is missed and less gel is wasted.

Which DST-GEL product fits your needs?

To make it simple:

Maintenance or manufacuring?

That’s the question.

Our current partners value efficiency, peace of mind, and environmental friendliness. DST-GEL delivers on all fronts, with a practical, adaptable tool that enhances performance and offers tremendous cost-effective solutions.

Developed and produced in our own lab

People from all over the world use our industrial cleaners. With good reason.

Our product quality is high due to our fantastic science team in our lab. They develop and produce all our water-based industrial cleaning products at our headquarters in Denmark.

That also goes for the DST-GEL portfolio, and as always these new products are true to our filosophy about creating high-performance cleaners formulated for minimum impact on people and the environment.

What do others think

“Finally, a company that understands the challenges of reman! You guys are the first to use gel – it’s a game-changer.”

“We’ve tried other solutions like foam, but when you rinse it off, it goes everywhere. Your gel is different. It’s applied directly onto the surface and stays put. Three minutes later, it’s rinsed off. No mess, no fuss.”

“Before when we had to leave the cleaning product on for 20-25 minutes and it still didn’t get things quite as clean.”

“This product is equally as good as the brake cleaner, and it is not labelled! It is exactly what we need.”

See how others do

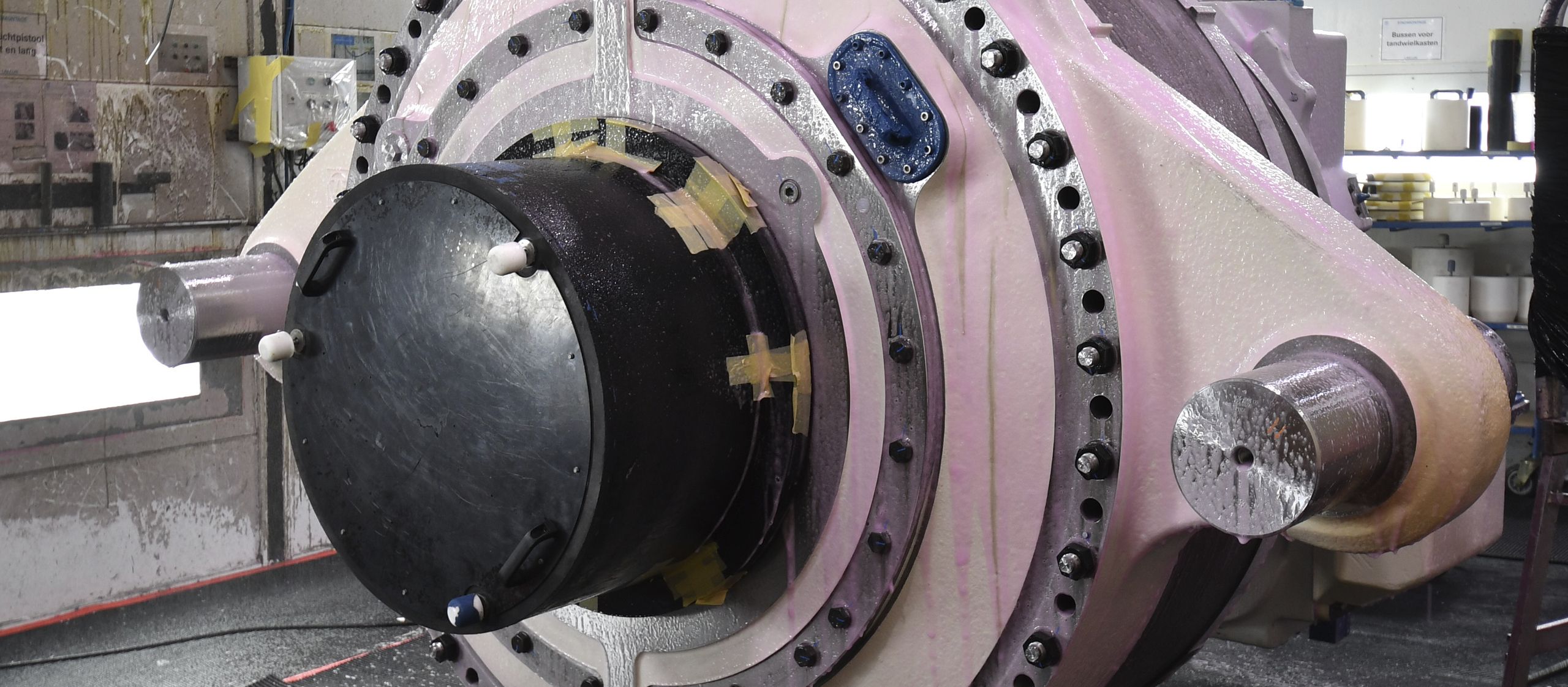

ZF WIND POWER

Perfect cleaning for the

wind turbine industry

At ZF Wind Power every single component inside the wind turbine gearbox is cleaned with DST-GEL. After assembly high quality cleaning with less manual handling is necessary, as next step in the process is lacquering and painting.