Effective cleaning in record time

Roland Fleischer GmbH is a German company specialising in CNC machining and contract deburring for hydraulic blocks and plates.

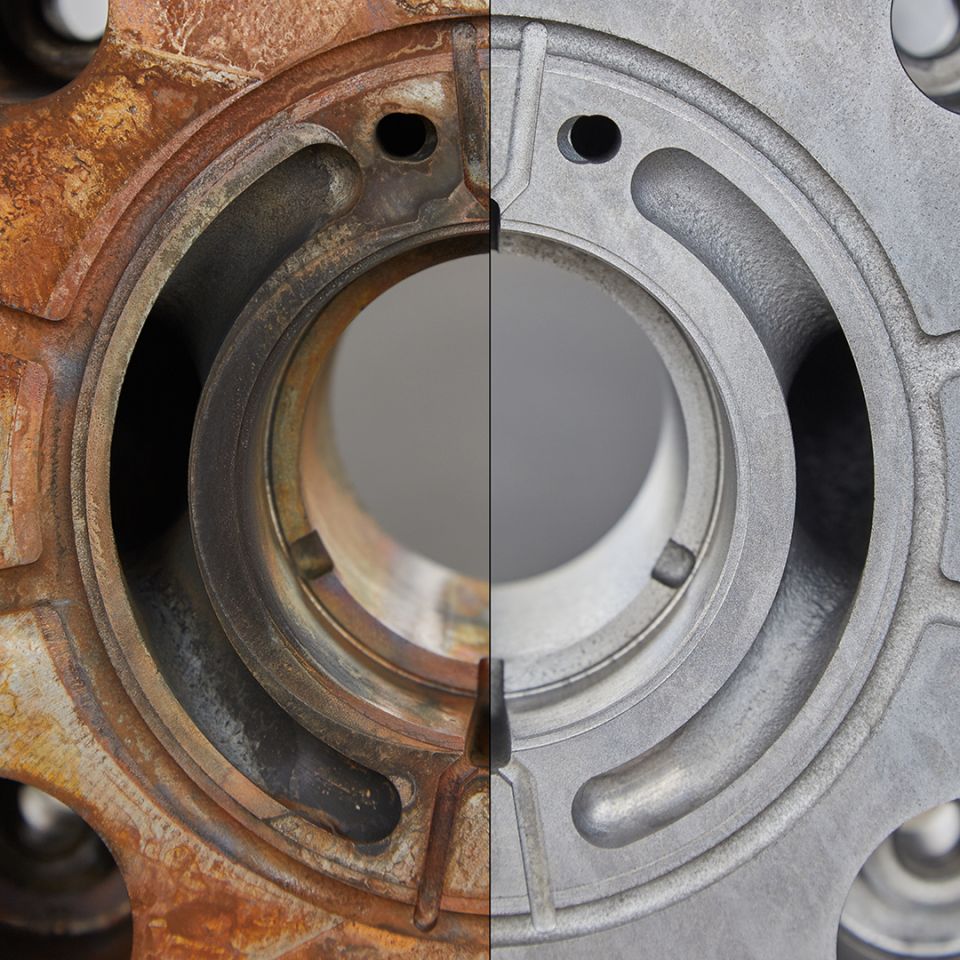

They provide high-quality, efficient deburring services, reducing the need for manual rework and improving the quality of finished products. Notably, they house one of the largest deburring chambers in Germany, showcasing their capacity and commitment to this specialized process. Their expertise in thermal deburring makes them a reliable partner for industries seeking precision and quality in their components.

Challenges and innovation

Entering the deburring industry, Roland Fleischer GmbH faced the immediate challenge of establishing an efficient cleaning process post-deburring. The company recognized the necessity for a collaborative approach, requiring the machine producer and chemical supplier to synergize their efforts. The goal was clear: to develop a setup that not only met the theoretical standards but also proved effective in real-world applications.

Individual solution for optimal results

The collaboration between DST-CHEMICALS and the MAFAC machine supplier emerged as the winning combination. Despite initial considerations regarding the cost of the cleaner, Roland Fleischer GmbH quickly realized that this investment paid off through outstanding performance and long-term savings. The long bath lifetimes and exceptional cleanliness achieved surpassed expectations. Moreover, the all-inclusive service and maintenance package provided by DST-CHEMICALS‘ experts ensured that the cost was justified.

Mr Steffen Fleischer, CEO, adds: “The saying ‘you get what you pay for’ has been validated and confirms that our approach of investing in quality to achieve good results has indeed given us a competitive advantage”.

Exceeding expectations with expertise

In the field of contract deburring and subsequent cleaning, Roland Fleischer GmbH places great value on expert advice to consistently ensure the highest quality standards. The support from DST-CHEMICALS was key in identifying the perfect setup tailored to their specific needs. After the installation and set-up of the new machine Roland Fleischer emphasised the great support, and the personalised solutions. Which have been invaluable and led to their operational success. This example shows how expert advice and customized solutions can help a company forward in a competitive industry.

Mr Steffen Fleischer concludes: “We were presented for a clear plan that matched our needs for a good cleaning process after deburring. This helped ease our worries and started a partnership built on trust and proven success. Not only were the immediate needs met but it also set the groundwork for a long-term collaborative partnership”.

Key outcome

- Efficient Deburring due to improved cleaning results.

- The deburring process became more efficient, reducing manual rework.

- Cost Savings: Despite initial cost concerns, the improved efficiency leads to long-

term savings. - The all-inclusive service-concept

means regular service and support,

simple ordering paths. - Strong Partnership:

The collaboration fostered a strong partnership for future ventures. - The collaboration between machine producer and chemical supplier is paramount for effective results.