Are you looking to modernize your industrial cleaning process? On this topic, we explore how you can achieve a shortened wash process with our cutting-edge cleaning solutions without compromising on the quality of cleaning. Say goodbye to long and painful cleaning procedures and say hello to efficiency and effectiveness. Discover the benefits of shortened wash processes in industrial parts cleaning.

Table of Contents

What qualifies for a long / short wash process?

In industrial parts cleaning, the length of the cleaning process can vary depending on several factors such as the level of dirt and contamination, the type of cleaning machine, the parts to be cleaned, and most importantly, the quality of the cleaning product.

Then what is a long wash process? It usually involves multiple steps with extended cleaning times. This can include pre-soaking, long wash cycle, rinsing, and drying. Using the wrong products and setting the time for unnecessary long, can be time-consuming and labour intensive. While you may find the result of this approach to give you some sort of cleanliness, the price is often greater than the result. For this approach often proves to be inefficient and costly in terms of time, money, and resources.

What is a short wash process then? A short wash process is ideally when you, with a cleaning machine and with the right products might we add, can clean the part, regardless of the size of it, in one go effectively. What contributes to the time spent on cleaning is that the cleaning method and the product do not wipe out oil, grease, lubricant and other contaminants thoroughly. When it does not, the parts often need at least a second turn and that extends the process. But more on that in a bit.

In contrast, there are several ways of achieving a short wash process that is both effective and does not compromise cleaning quality.

Does the cleaning time affect the cleanliness of the parts?

It depends. It depends on the right chemistry. On the right machine. On the right products. On the right people.

So, what approach is good here? Is it spending too much time cleaning or worrying that a short cleaning process may not do it for you? Indeed, the time spent on cleaning parts plays a crucial role in cleanliness. Let us put it like this: You are spending a lot of time on parts cleaning where you go through many steps, potentially you are re-washing parts, and maybe also on high heat, thinking that it will do the job, and the result is cleanliness, perhaps.

Read more about how we ensure Industrial cleanliness here

However, in some cases, a prolonged cleaning process may not necessarily lead to better cleaning results. What if you are cleaning it with the wrong products or the applied method is wrong? In doing so, the equipment may be overexposed to cleaning solutions or extended soaking times may cause damage to the equipment or result in residues being left behind on the surfaces. This can compromise the cleanliness of the equipment and lead to potential issues down the line.

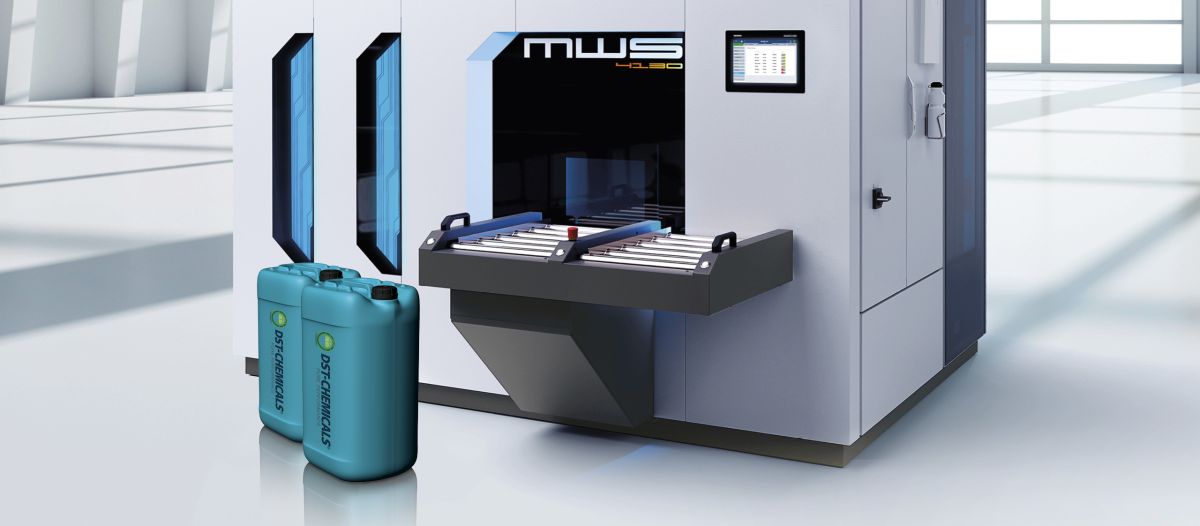

What if we told you that you can achieve cleanliness, guaranteed in fact, in no time? You just use our DST-product in combination with your cleaning plant and voila! Fewer steps, in one go and cleaning those bad-for-businesses grease, grime oil away from parts? With our products you get this and more. Our cleaners’ ability to demulsify the oil from water prolongs the need to frequently change your bath water. This means that you can also save time from changing the bath water in your facility.

Through a short cleaning process, you can save valuable amount time, money, resources, decrease the cost of manhour and will likely also increase productivity. All while achieving a effective and thorough cleanliness.

One other thing… Our products work exceptionally well with a cleaning machine. So, let’s say that you want to invest in a washing machine. Which we are all here for. But you may not have the space for it. And if the parts you want to clean are too big to fit in a machine. Don’t worry, we and our DST-GEL’s got your back. This product is a ready-to-use to spray on parts. After a few minutes, you can rinse if off and there you go. Non-hazardous, practical, and cost-effective gel. It is just a life saver when the work needs to be done fast and effectively.

What are the reasons that the cleaning process gets prolonged

There are several reasons why the cleaning process may become prolonged, impacting efficiency and potentially compromising the cleanliness of the parts.

First, the wrong cleaning solution is being implemented on the given parts. This can prolong the wash process as they may not effectively break down oil, grease and contaminants which in turn may lead to repeated cleaning cycles to achieve the desired level of cleanliness.

Second, the cleaning method likewise is decisive here. Traditional cleaning like scrubbing and brushing may be time consuming. Likewise, outdated cleaning machines can contribute to prolonged wash process as they may not provide sufficient coverage.

Third, this is a little continuation of what we’ve said previously about using the right product for the industrial parts. Because heavily soiled or contaminated parts may require more time and effort to clean thoroughly. At DST-CHEMICALS we make sure to provide and recommend to you a water-based cleaning solution that meets your specific needs.

Finally, not everyone is good at cleaning. Insufficient training in proper cleaning and the procedures with how to handle cleaning can lead to inefficiencies and mistakes that prolong the wash process. Fortunately, this can be improved. At DST-CHEMICALS, we educate you, our customers, on the best practices for cleaning parts with our products and show you the best ways to clean.

Want to discover how others do?

We are helping other great companies achieve optimized and shorten cleaning processes. See for yourself below how we’ve managed to do so!

Our best advice to shorten your cleaning process with industrial parts?

All right, with the number of customers we have helped in this field, we do have some general recommendations for you to shorten your cleaning process with industrial parts.

We provide a range of high-performance cleaning solutions to effectively remove dirt, grease, grime, and contaminants from industrial parts. The product that we hand-pick for you is based on a Product Selector Report from our own tech lab. This way you get a product that will guarantee you result where your cleaning will save you time.

To ensure your staff is fully equipped to handle our cleaning solutions the right way, our Technical Advisor will support and train your staff. In addition to sharing the best cleaning practices, tips, and tricks. We will also aid you in changing the bath. It’s in our experience that customers’ need to change the bath will decrease drastically after starting to clean with our products. So that will likely shorten the wash process.

We are in it for the long run, which means our commitment goes beyond the initial conversion. We provide expert knowledge and service – the way it should be.” We are so dedicated about the after-sales service that we have made it our vision.

When you choose DST-CHEMICALS, you are not only choosing a supplier. You are choosing a partner that always goes the extra mile of helping you despite you having received and achieved success with your water-based cleaning solution. A technical advisor pays you a visit after success to maintain those results. Why? Because that is what we mean by being partners.

Questions and Answers

How do you optimize your parts cleaning process?

The effectiveness of your cleaning process depends on the right chemistry, products, and methods. Spending excessive time on cleaning doesn’t always guarantee better results; using the wrong products or methods can lead to dissatisfying or undesired results. With our DST-product, you can achieve guaranteed cleanliness in fewer steps, effectively removing grease and grime while prolonging the time between bath water changes. This not only saves time and resources but also increases productivity. For smaller parts, our non-hazardous DST-GEL is a practical, ready-to-use solution that allows for quick cleaning—just spray, wait a few minutes, and rinse.

How can we help shorten the washing process for customers when cleaning parts?

We recommend our high-performance cleaning solutions, specifically selected based on a Product Selector Report from our tech lab, to effectively remove dirt, grease, and contaminants. Our Technical Advisor will train your staff on best practices and assist with bath changes, which typically reduce the need for frequent changes after using our products, ultimately shortening your wash process. At DST-CHEMICALS, we are committed to long-term partnerships, providing ongoing support and expert knowledge even after your initial success. Our technical advisors will follow up to help maintain your results, ensuring you have a reliable partner in your cleaning efforts.

Learn more about the products related to this article

At DST-CHEMICALS, we continuously work to improve the efficiency and environmental performance of industrial cleaning. Our focus is on developing solutions that reduce energy use, minimise waste, and extend bath lifetime — helping customers achieve cleaner parts with fewer resources..