Maintaining the performance and longevity of engines is crucial for optimal operation, and one often overlooked aspect of this maintenance is engine degreasing. Engine degreasing involves the thorough cleaning of engines and engine components to remove built-up grease, oil, and grime. This process plays a vital role in identifying potential issues, improving efficiency, and preventing overheating. Follow along and discover the importance of engine degreasing and its impact on engine maintenance.

Table of Contents

Why maintaining clean engines is crucial for businesses

Maintaining clean engines is essential for ensuring optimal performance and longevity. Engines are critical components in various industrial applications, powering machinery and equipment that drive production processes. A clean engine operates more efficiently, reducing energy consumption and minimizing the risk of overheating, which can lead to costly downtime and repairs.

Regular cleaning of engines helps prevent the accumulation of dirt, grease, and other contaminants that can impair functionality. Contaminants can cause increased friction, leading to wear and tear on engine components, which may result in premature failure. This is why implementation of a routine cleaning schedule is important; businesses can enhance the reliability of their operations and extend the lifespan of their engines.

Engine degreasing is a vital aspect of this maintenance process. Effective degreasing removes built-up grime and oil, allowing engines to run cooler and more efficiently. This not only improves performance but also helps in identifying potential issues early, enabling timely maintenance and reducing the likelihood of unexpected breakdowns.

Methods of engine degreasing

Engine degreasing is a critical process in industrial cleaning, aimed at removing grease, oil, and other contaminants from engine components. Various techniques and products are employed, each with their own advantages and disadvantages.

Traditional methods;

Solvent-based cleaning:

Products: Common solvents include mineral spirits, kerosene, alcohol, and gasoline.

Technique: These solvents are applied directly to the engine surfaces, often using brushes or rags to scrub away grime. The solvents dissolve grease and oil, making it easier to wipe away contaminants.

Advantages: Effective at breaking down heavy grease and oil: relatively inexpensive.

Disadvantages: High volatility and flammability; potential health hazards due to fumes; environmental concerns regarding disposal.

High-pressure washing:

Technique: High-pressure water jets are used to blast away dirt and grease.

Advantages: Quick and effective for large surfaces; can reach difficult areas.

Disadvantages: May not remove all contaminants, can lead to high water consumption, and can cause water damage, including increased risk of rusting due to residual moisture.

Modern & Eco-Conscious options:

Water-based degreasers:

Products: These cleaning solutions contain water and biodegradable ingredients, such as surfactants, detergent, de- and emulsifiers. These degreasers are designed to break down grease without harming the environment.

Technique: Apply the DST-DEGREEZ at the suggested concentration in the cleaning plant to clean the parts.

Advantages: Safer for workers and the environment; effective on a variety of contaminants.

Disadvantages: The cleaning process may take longer if the appropriate cleaner is not used.

Ultrasonic cleaning:

Technique: Uses high-frequency sound waves in a liquid solution to create tiny bubbles that remove contaminants.

Advantages: Gets into all the tight spots for a super thorough clean. Works great with the DST-DEGREEZ products.

Disadvantages: The equipment can be pricey and might not work for every engine part.

While traditional methods like solvent-based cleaning and pressure washing are popular for their effectiveness and low cost, they have major downsides, especially regarding health and environmental safety. Modern, eco-friendly options might need a higher upfront investment, but they bring long-term benefits like better worker safety, less environmental impact, and meeting stricter regulations.

What is the best way to degrease an engine?

It all comes down to using the right degreaser. To clean effectively and maintain quality, you need to consider two things: 1) What material are you degreasing? 2) What cleaner are you using? You might have an engine in front of you and use an expensive cleaner that doesn’t work on that metal type. That wastes your time, money, and resources.

At DST-CHEMICALS, we have over 35 years of experience helping customers with cleaning challenges. Our approach is simple: Pure Performance. Tell us your specific cleaning needs and let us know how clean is clean in your line of business. In the field of remanufacturing and maintenance, our experience consistently points to our DST-DEGREEZ/9E. This product is specifically designed for the industry and is suitable for all metal types, making it an excellent choice for general engine cleaning. It effectively removes grease, oil, and contaminants from various engine parts.

To get the best result, make sure that you have a cleaning plant, as the DST-products are developed for parts cleaning applications.

You can read more about DST-DEGREEZ products here.

If you do not have a cleaning machine but still needs to tackle parts cleaning challenges, we recommend DST-GEL/2. This ready-to-use cleaner that is great for removing sticky passivation oils, burnt-on oils and grease, tar, brake dust, small metal parts. It is timesaving, cost effective, and delivers fast results. Plus, it is not labelled: DST-GEL is non-hazardous and made with safe ingridients, making it effective against tough, baked-on grime. baked-on grime. It’s well-suited for remanufacturing, and designed for easy, safe handling while maintaining strong cleaning performance.

You can read more about our DST-GEL here:

Why you should be using a cleaning machine

Even with modern cleaning technologies available, many industrial facilities still rely on traditional methods without washing machines. This can be due to familiarity, perceived cost savings, or a lack of awareness about the benefits of modernization. However, there are compelling reasons to transition to machine-assisted cleaning methods:

1. Efficiency: Cleaning machines can significantly reduce the time and labour required for degreasing tasks, leading to faster turnaround and increased productivity.

2. Consistency: Clean baths can really up your game. That is why we perform regular service visits performed by our Service Advisors to maintain those bath lifetimes. Free of charge that is. Clean baths help you achieve optimized cleaning results, ensuring all components are thoroughly cleaned for longer. And saving you money and time. Time and money.

3. Safety: Modern cleaning systems offer an efficient, rapid, and innovative solution for cleaning your metal parts. These systems work well with our water-based cleaners, which are designed to separate the oil from water and operate at lower temperatures. Unlike traditional cleaning methods using petroleum or acetone, which pose health risks and environmental harm, our approach prioritizes safety and sustainability.

4. Regulatory compliance: As environmental regulations become stricter, using cleaning machines and eco-friendly cleaners can help businesses stay compliant and avoid potential fines.

Benefits of regular engine degreasing

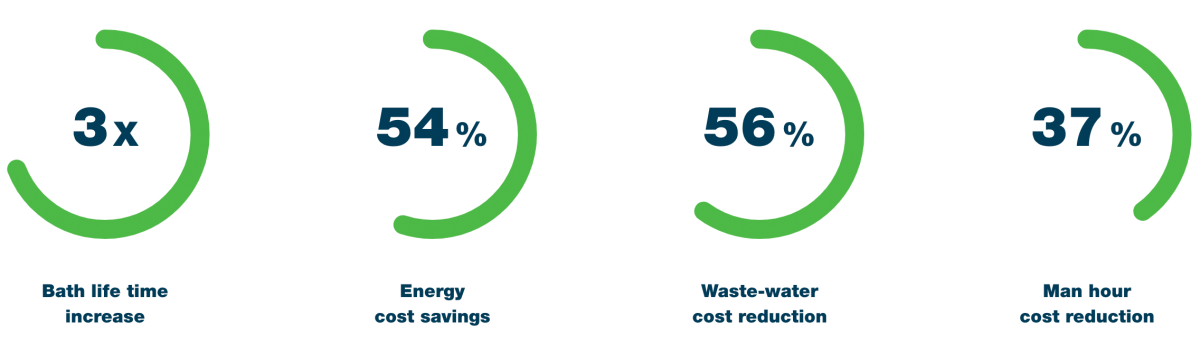

Regular maintenance and engine cleaning are crucial practices. Keeping parts clean is essential for maintaining efficiency and preventing costly replacements. By ensuring regular cleaning, you can extend the lifespan of your equipment and avoid the need for expensive new purchases. This is exactly what others do:

Choosing the right engine degreasing service provider

We believe that our commitment to you goes beyond just the initial stages; it continues even after the conversion to a DST-product has been completed. We are always ready to provide expert knowledge and exceptional service whenever you need it—that’s just how we do things.

To make sure that everything runs smoothly, our Technical Advisor will conduct regular service visits to address your needs. Additionally, our industrial cleaning solution guarantees Pure Performance, delivering optimal results. Our Technical Advisor will also offer training for your staff, giving them with valuable insights and best practices for maintaining the bath efficiently.

Questions and Answers

What is the best way to degrease an engine?

Choosing the right degreaser depends on two key factors: the material you want to degrease and the appropriate cleaning product. At DST-CHEMICALS, we leverage over 35 years of experience to recommend the best water-based solutions, like DST-DEGREEZ/9E for maintenance and remanufacturing. It is suitable for all metal types and effective in removing grease from engines and components. If you don’t have a cleaning machine, we recommend DST-GEL/2, a ready-to-use, non-hazardous cleaner that effectively removes oils and grime while being safe for both employees and the environment.

What are the best methods for degreasing an engine?

1. Water-based degreasers: Biodegradable and water-based degreasers are applied in a cleaning plant with the parts.

Advantages: Safer for workers and the environment. Are often safe to use on a variety of materials including plastics and rubbers. Can be used on all kinds of metal. Leave no residue which means there is no need for additional cleaning

Disadvantages: May not do the job, if the wrong degreaser is applied.

2. Ultrasonic cleaning: Employs sound waves to create bubbles that dislodge contaminants.

Advantages: Thorough cleaning, especially for intricate parts.

Disadvantages: Higher initial equipment costs and may not suit all components.

3. High-pressure washing: Utilizes water jets to remove dirt and grease.

Advantages: Quick and effective for large areas.

Disadvantages: May not remove all contaminants and can lead to rust or corrosion if not handled properly.

4. Solvent-based cleaning: Uses solvents like mineral spirits and kerosene applied with brushes or rags.

Advantages: Effective and inexpensive.

Disadvantages: High flammability, health hazards from fumes, and environmental concerns. Can cause damage to a variety of materials including rubber and plastics.

While traditional methods are effective, they pose health and environmental risks. Modern, eco-friendly options provide long-term benefits, including improved safety and compliance with regulations.

What benefits will regular degreasing of engines grant you?

1. Improved performance: A clean engine operates more efficiently, enhancing fuel efficiency and reducing operational costs. Regular degreasing minimizes dirt and grease buildup, leading to fewer unexpected breakdowns and smoother machinery operation.

2. Extended parts lifespan: Regular degreasing removes harmful substances that can cause corrosion and wear, helping to protect engine components and extend their operational life.

3. Cost savings: Preventative maintenance through regular degreasing reduces the likelihood of costly repairs and minimizes downtime. Well-maintained equipment also retains its value better than neglected machinery.

4. Environmental compliance: Clean engines operate more efficiently, resulting in lower emissions, which is crucial for industries subject to environmental regulations. Regular degreasing ensures proper disposal of harmful substances, protecting both people and the environment.

Investing in water-based degreasers and cleaners means investing in the long-term efficiency and sustainability of your operations. Keep your engines running smoothly and responsibly with the power of water-based cleaning solutions.

Nick Bjerregaard

International Process & Technical Manager

Technical Manager at DST-CHEMICALS: 20 years of chemical industry experience, driving innovation, efficiency, and environmental sustainability.

Environmental, social and governance

At DST-CHEMICALS, sustainability is at the heart of everything we do. We engaged with key stakeholders, including our team of suppliers, to ensure we focused on what truly mattered. Ready to see the full picture? Keep an eye out for our ESG report, where we share the next steps in our journey to sustainability.