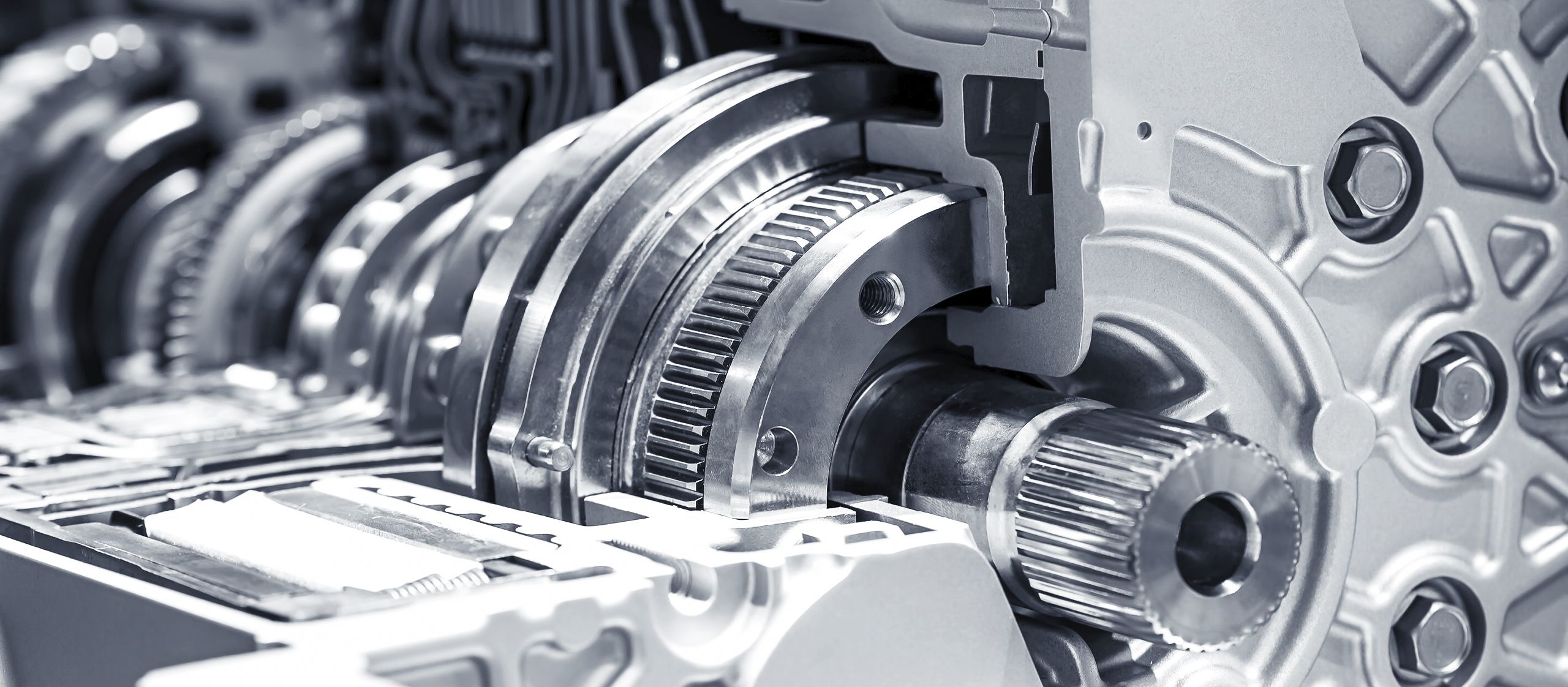

The surface treatment of metal is an essential part of the production process. The surface of components is processed to improve or change mechanical, chemical or optical properties. Surface treatment increases the service life and efficiency of components, helps reduce costs and protects components from corrosion.

With over 35 years of experience, we at DST-CHEMICALS have specialized in the degreasing and cleaning of metals. With our carefully selected and environmentally friendly products, we are at your side as experts in the treatment of metals.

Table of Contents

This is how surface treatment works

Before metals can be painted, welded, varnished, or assembled, their surface must be processed to ensure optimal further processing. Surface treatment includes everything from removing contaminants, rinsing with post-phosphates, applying organic-inorganic sealers, and then rinsing. This can provide a surface to which paint and other coatings can adhere well.

Various surface treatment processes

The list of different processes in the field of surface treatment is long. Depending on the material, degree of contamination and the goal of cleaning, different methods are more suitable than others. In the online landscape the species are classified as follows:

Mechanical surface treatment

This type of surface treatment uses mechanical forces and energy to change the surface of a material. This group includes processes such as grinding, honing, polishing, brushing, blasting, lapping, burnishing, explosive cladding, and barrel polishing.

Chemical surface treatment

This type of surface treatment uses chemical processes to specifically change the chemical composition and surface structure of a material. This is typically done by applying a chemical solution or coating material to the surface of the workpiece. Chemical surface treatment includes processes such as degreasing, pickling, etching, shining, chromating and phosphating.

Coating the surface

Coating is one of the most common processes. Here, as the name suggests, a thin layer is applied to the material. This group includes processes such as painting, powder coating and chrome plating.

Removing the surface

Surface removal is a method of surface treatment in which material is removed from the surface of a component with the aim of achieving specific effects. This process is often used to smooth the surface, remove contaminants, change surface texture, or remove layers. Processes such as burnishing and electropolishing can be found here

Properties achieved through surface treatment

Surface treatment is an important aspect that helps extend the life of various metals and other components. It’s no surprise that surface treatment is an integral part of so many industries. These include the automotive industry, construction, container manufacturing, the electrical industry, medical technology, industrial plants, laboratory technology, and aerospace. The components covered range from eyeglass frames to car parts to screws, nuts, bolts, various tools, and many other parts.

Various properties can be achieved on material surfaces through surface treatment. This includes:

- Protection against corrosion: Surface treatments can help protect metals from rust and corrosion, extending the durability and lifespan of the materials. Special industrial cleaners can be used for the treatment. At DST-CHEMICALS we have developed DST-PAS, a water-based cleaner that effectively protects components from corrosion.

- Improved hardness and abrasion resistance: Certain treatments, such as plasticizing or nitriding, can increase the surface hardness and abrasion resistance of materials, making them more resistant to wear.

- Increased Adhesion: Surface treatments improve the adhesion of coatings, paints and other materials to the surface, providing better adhesion and durability.

- Optimized appearance: Sometimes the surface treatment also serves optical reasons. Here the appearance of materials can be improved or modified by making them appear smoother, shinier, or even decorated through treatment.

- Better electrical conductivity or insulation: Depending on requirements, surface treatments can improve electrical conductivity or provide electrical insulation.

- Improved thermal and acoustic insulation: Certain surface treatments can improve the thermal and acoustic insulation of materials.

Surface treatment the DST-way

Treat your metal parts with our one of our many products like DST-DEGREEZ and DST-DERUST which are ideal for treating various metal surfaces.

No solution fits everyone. That’s why we need to understand your production processes before we can clean them up. What do you need? And what is your specific challenge? When we understand the bigger picture, our brightest minds put in place the smaller pieces. We develop, evaluate, test, implement and maintain your water-based cleaning solution – with local service teams around the world. Pure performance – that is our promise to you. Read how we have helped other companies take their cleaning processes to the next level.

Eco-friendly cleaning solutions for your surfaces

With over 35 years of experience, we are a leading manufacturer in the production, of water-based cleaners for various surfaces. Through individualized product developments, we guarantee high-quality results in the cleaning and treatment of metal surfaces and other materials.

When you work with us, you get a water-based cleaning solution that eliminates grease, corrosion, and harmful processes. You get a solution that is environmentally friendly, because of its high efficiency at low temperatures. This helps you reduce costs, raise standards, and make your production shine.

Questions & Answers

What kind of surface treatments are there?

The list of different surface treatments is long. However, we often talk about mechanical and chemical surface treatment. Mechanical surface treatment uses mechanical forces to change the surface of a material, while chemical surface treatment uses processes such as degreasing, pickling, or etching to change the outermost layer of materials.

What is meant by surface treatment?

Surface treatment is a process in which the surface of a material is specifically changed to achieve certain properties. The treatment of surfaces protects the material from corrosion, improves the adhesion of coatings, increases the hardness, and improves the appearance of the various surfaces.

Environmental, social and governance

At DST-CHEMICALS, sustainability is at the heart of everything we do. We engaged with key stakeholders, including our team of suppliers, to ensure we focused on what truly mattered. Ready to see the full picture? Keep an eye out for our ESG report, where we share the next steps in our journey to sustainability.