Clean under pressure – and in control

MANUFACTURING

Clean under pressure – and in control

How to ensure quality and sustainability

with every wash

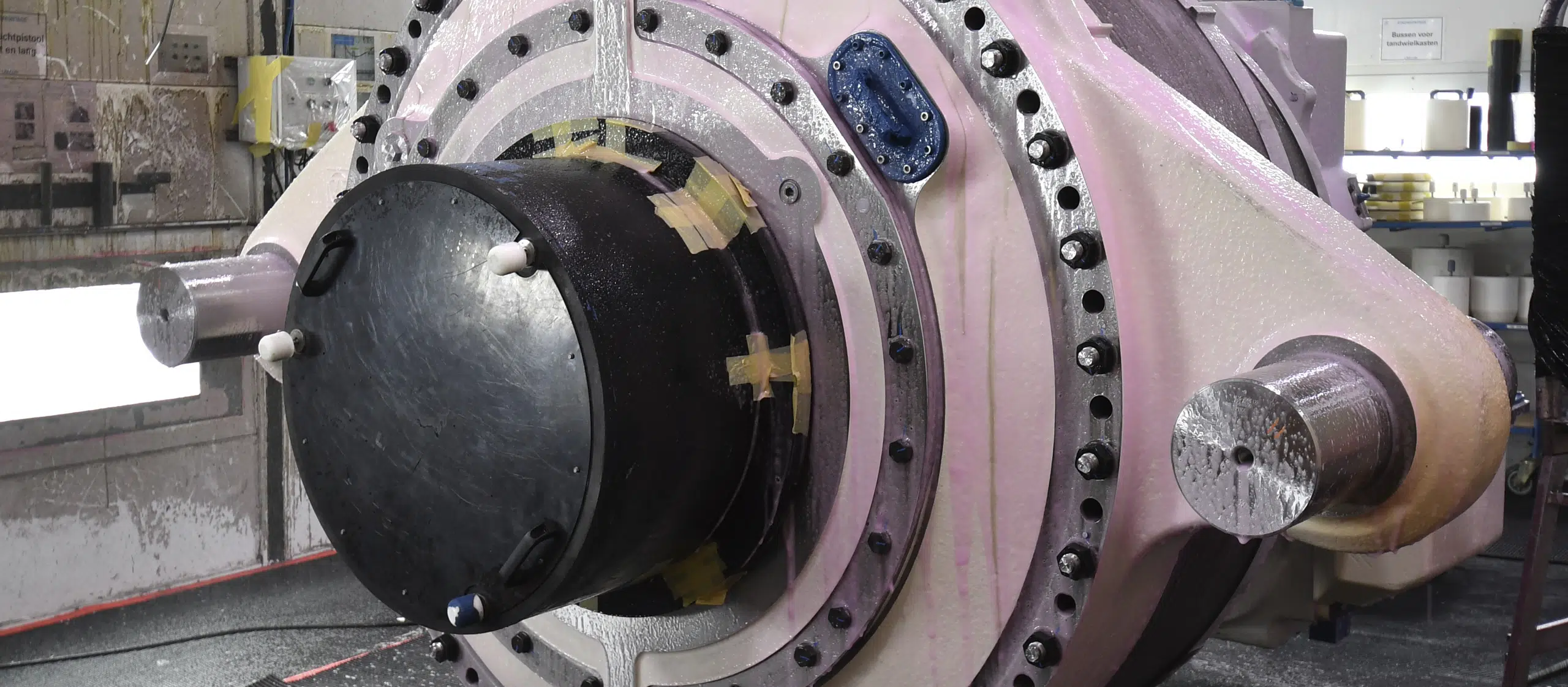

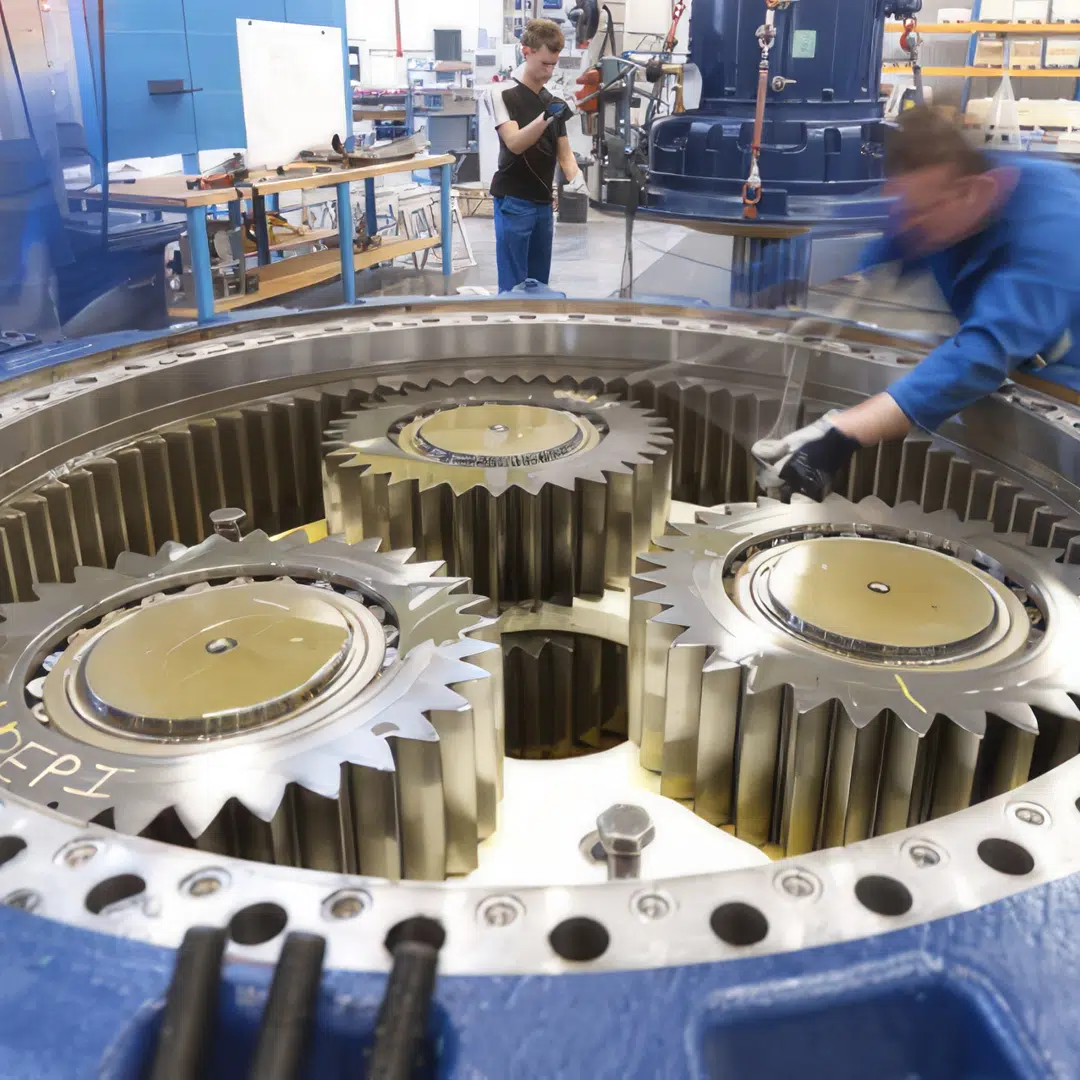

Danfoss Power Solutions is a global leader in mobile and industrial hydraulics, electrification, and control systems, serving sectors from construction and agriculture to marine and offshore industries.

At their Dutch facility in Eindhoven, they develop and test hydraulic cylinders for demanding applications, including offshore oil rigs and aerospace simulators for SpaceX. With components operating under pressures up to 600 bar, ensuring cleanliness and reliability is paramount.

High-performance cleaning

for high-pressure components

To keep their production running safely and reliably, Danfoss turned to DST-CHEMICALS and Eco-Point. The combination of DST-DEGREEZ cleaners and DST-PAS passivation agents in their Kermad industrial washers ensures consistently clean results and extended bath lifetime.

Individual components are effectively cleaned using Eco-Point’s Safeco while stainless steel pipes are fully degreased with E.P. Bio Degreaser Pure – both ready-to-use products.

The results? A spotless finish and a stable, repeatable cleaning process that ticks every box – including compliance with Danfoss’ strict 5S and quality standards.

Sustainability without compromise

sustainability is built into Danfoss’ DNA. The switch to

water-based, biodegradable cleaners has significantly

reduced chemical exposure, improved workplace safety,

and aligns perfectly with the environmental goals of the

company. Fewer breakdowns, more control, and better

results – all while lowering environmental impact.

More than just products – real partnership

Pure Performance approach: hands-on support,

tailored product selection, on-site assistance, and

proactive follow-up. DST-CHEMICALS and Eco-Point

delivered more than just products – they delivered

peace of mind. Regular follow-ups ensure the cleaning

processes stay optimised each and every day.

Visible results – and a professional impression

Cleanliness isn’t just a performance metric at Danfoss – it’s part of the customer experience. From a bulletproof-glass viewing room, visitors see a clean, well-organised environment that reflects the high standards behind every Danfoss product.

Sjaak Hermens, Head of Technical Services at Danfoss Power Solutions, says: “To be honest, we were a bit skeptical at first. Would these products really be powerful enough for our heavy-duty applications? And what about compatibility with our materials and machines? Thanks to expert guidance and a step-by-step approach, all these concerns were completely dispelled.”

And Sjaak concludes: “We recommend the products and services of DST-CHEMICALS and Eco-Point to companies with technically complex processes, which have high demands for cleanliness and want to work sustainably at the same time. Whether in petrochemicals, maritime applications or heavy industry – this partnership shows that working sustainably and achieving top results go hand in hand.”

Key outcome

- Consistently clean and reliable results.

- Lower chemical exposure

-> improved workplace safety. - Longer bath life time.

- Reduced down time and improved process reliability.

- Strong support from product selection to after sales service.