Less energy used. Cleaner parts achieved

Remanufacturing

Less energy used.

Cleaner parts achieved.

New technologies made possible thanks to DST know-how

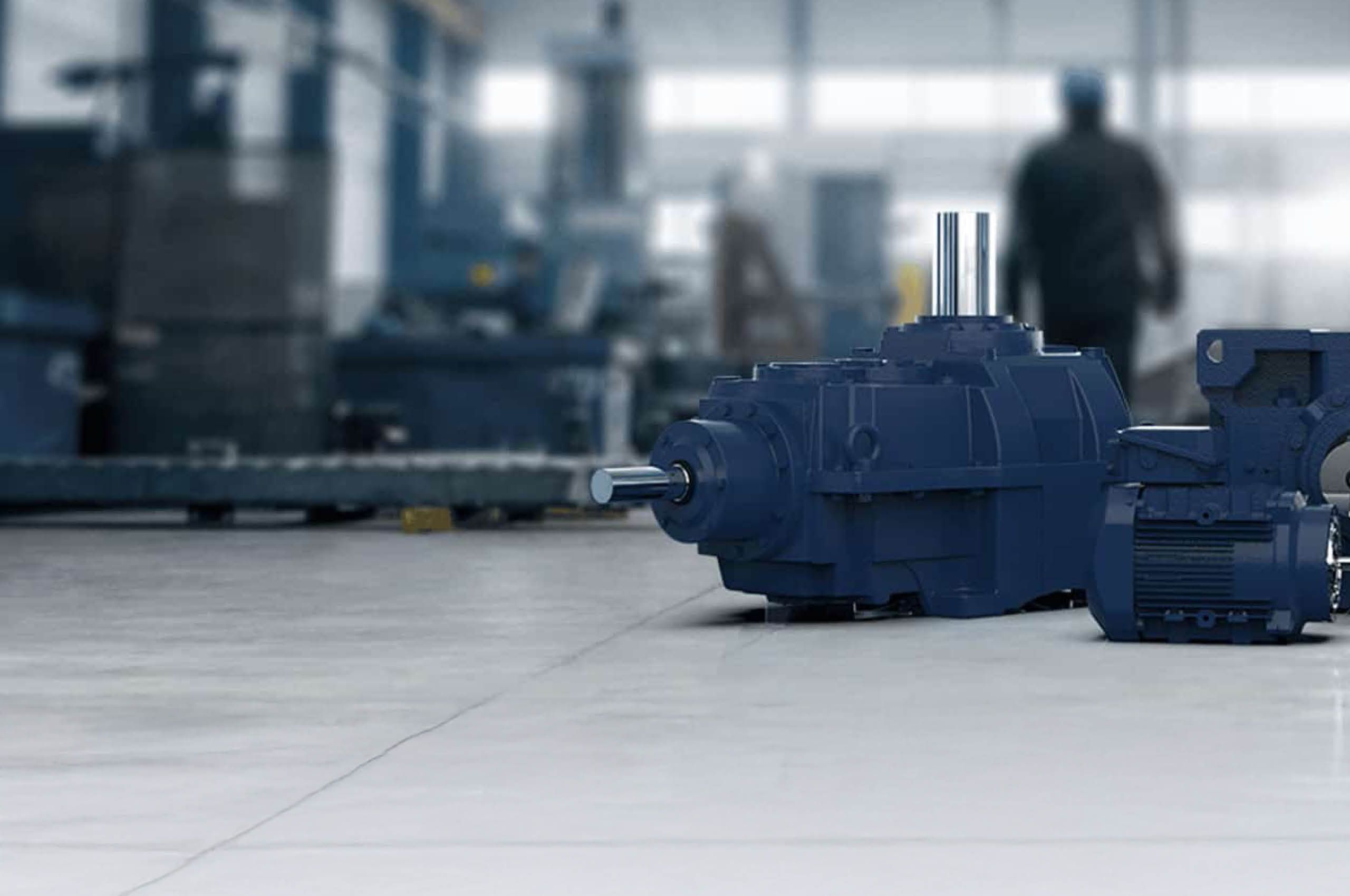

Sumitomo Drive Technologies is one of the world’s leading manufacturers of high-quality drive solutions – with over 130 years of experience and a clear focus on innovation, quality, and sustainability.

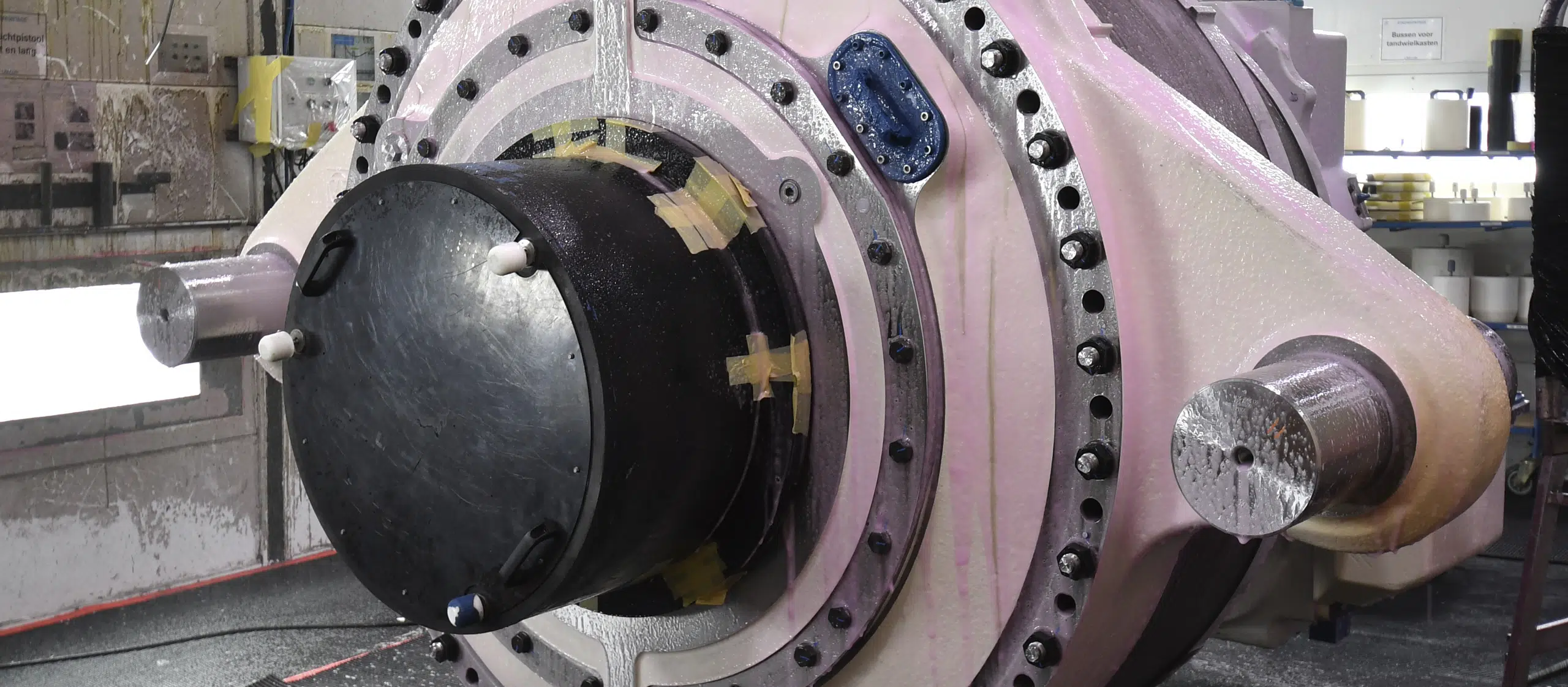

The company follows a group-wide ESG strategy and actively invests in energy-efficient processes, climateneutral energy sources, and long-term CO2 reduction. At the German site in Markt Indersdorf, these ambitions are being turned into action. Production is being modernised with a focus on sustainability – combining environmental responsibility with technical excellence. That includes looking at every step of the process. Also cleaning.

Cleaning with a sustainable focus

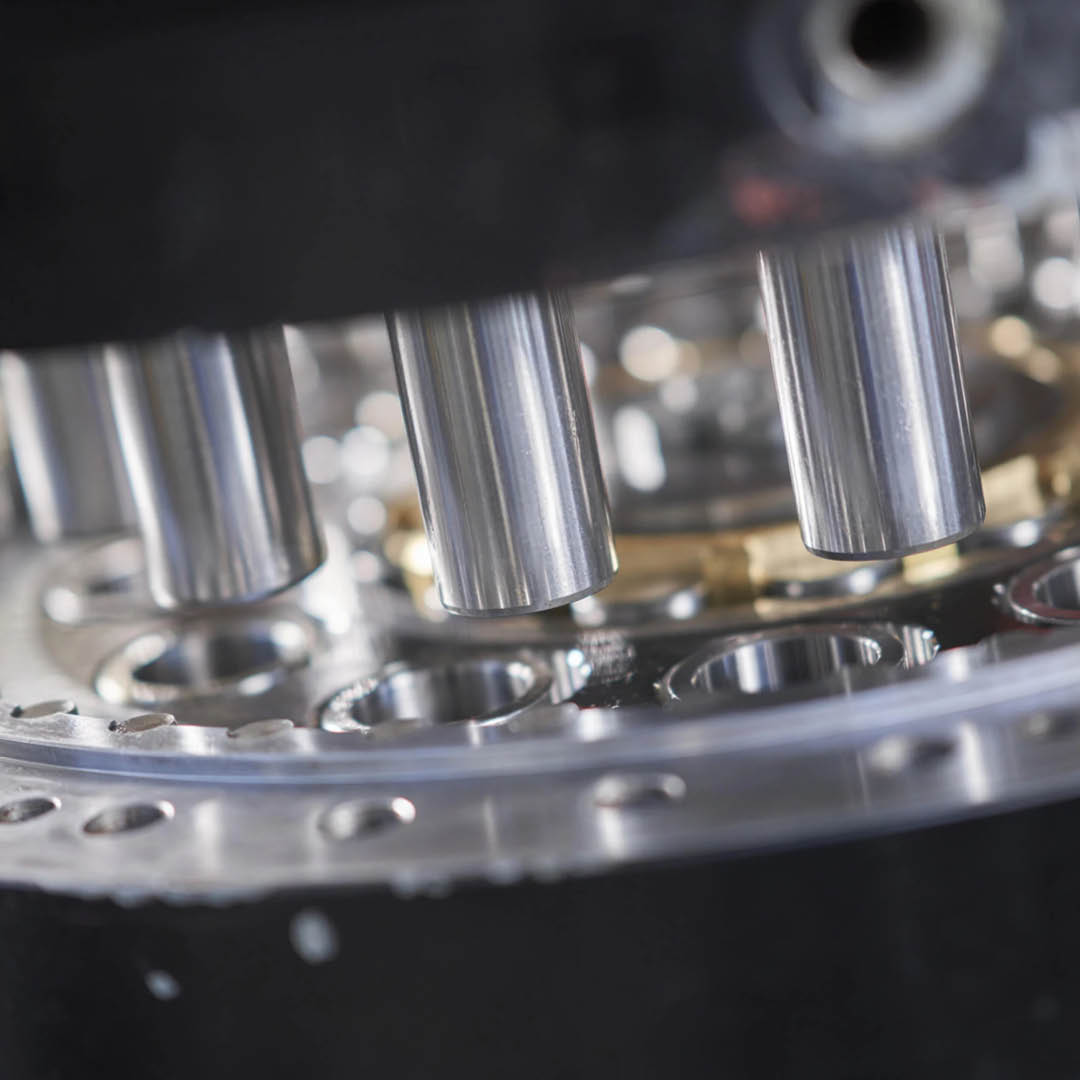

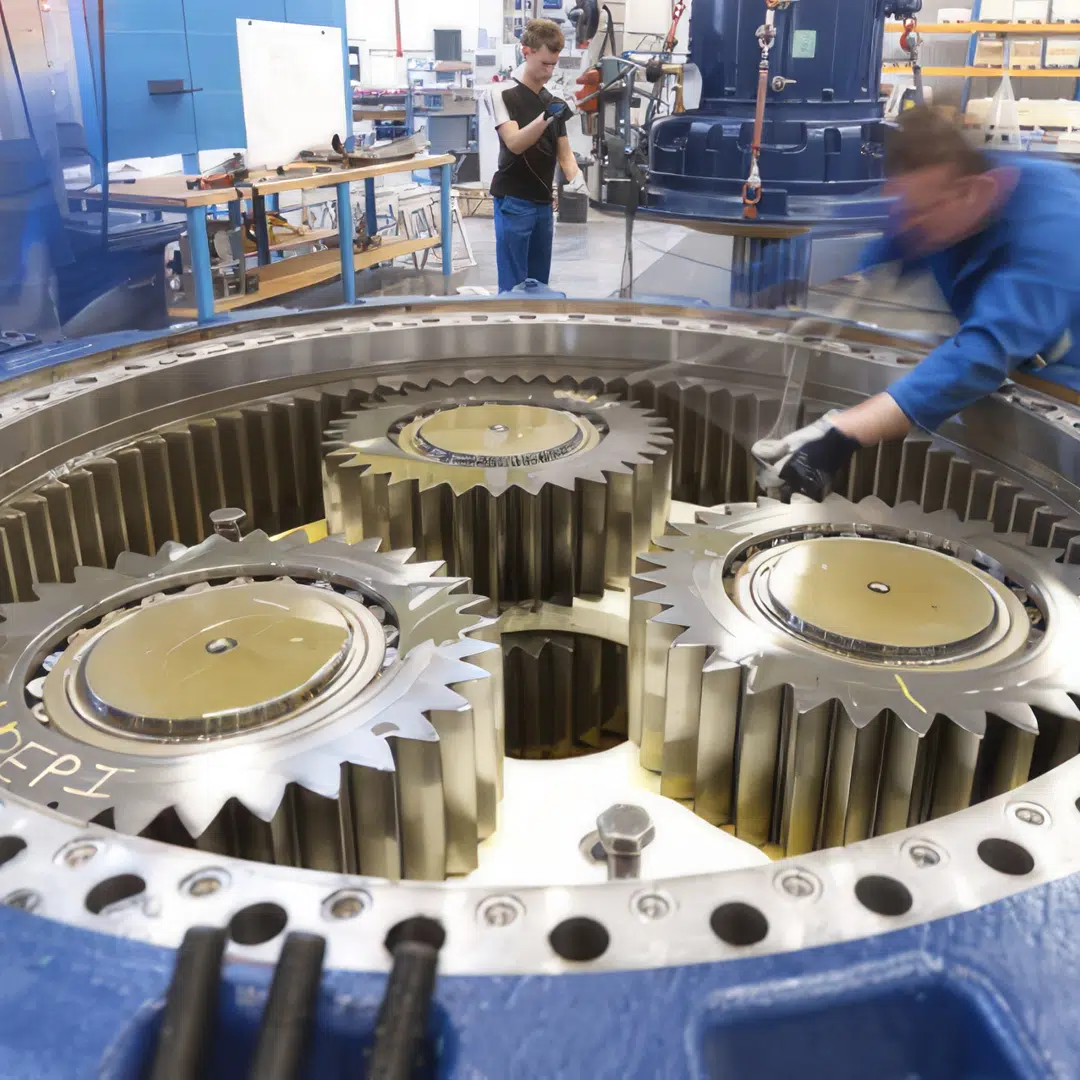

The aim of the collaboration was to increase energy efficiency in the remanufacturing process without compromising component cleanliness. The existing cleaning solution operated at 80 degrees, which resulted in high operating costs – especially during continuous use in two-shift operation. At the same time, heavily contaminated components such as greasy ball bearings and parts with complex geometries had to be cleaned reliably, which was often not the case. The existing setup wasn’t up to the task and required time-consuming manual re-work.

Based on an on-site process analysis and a Product Selector Report, we recommended Ali Özkan, Service Manager at Sumitomo Drive Technologies, to use the water-based cleaner DST-DEGREEZ/9EP. The product was recommended due to its high performance at significantly lower temperatures.

The result? A reduction in cleaning temperature from 80°C to 55°C – with improved cleaning performance at the same time. And despite high contamination levels, a bath lifetime of six months was achieved.

The right solution, powered by DST know-how

A key factor for the optimal solution was the integration of a low-pressure cleaning unit from ph-cleantec, operating in a closed loop with the existing PERO ROBOMAT system – commonly found in remanufacturing environments.

Grease-filled bearings are now cleaned using a hand-held lance in a separate tank within the low-pressure system. This protects the cleaning agent and extends the bath life of the main installation. Parts with undercuts – which previously led to spray shadows in the PERO – are now efficiently pre-cleaned with the lance in just seconds. DST-CHEMICALS supported not only with product selection, but also with the idea and integration into the existing equipment setup.

Ali Özkan concludes: “DST-CHEMICALS is not just a supplier – they’re a true partner. It wasn’t just about recommending a cleaner – it was about jointly developing an improved process with long-term impact. Combined with their regular service visits, this has improved our cleaning operations significantly.”

The improved cleaning process supports Sumitomo Drive Technologies’ sustainability goals – while also delivering significant economic benefits.

Key outcome:

- Reliable cleaning of even complex and heavily soiled components · Using non-hazardous products for a safer work environment.

- High energy savings through a 25°C lower process temperature.

- Effective problem-solving with expert technical advice

- Integration of a low-pressure pre-cleaning unit in a closed-loop setup.

- Ongoing service – including process optimisation and staff training.

- Sustainable improvements in cleaning quality and operating costs.

- A trusted partnership for future projects.