Perfect cleaning for the

wind turbine industry

Manufacturing

Optimised cleaning processes ensures

high quality

How ZF Wind Power optimised their cleaning process and boosted productivity

ZF Wind Power puts wind turbines in motion and their advanced technology and service solutions contribute to the transformation of the global energy system, in which reliable, robust and efficient products and systems conserve precious resources.

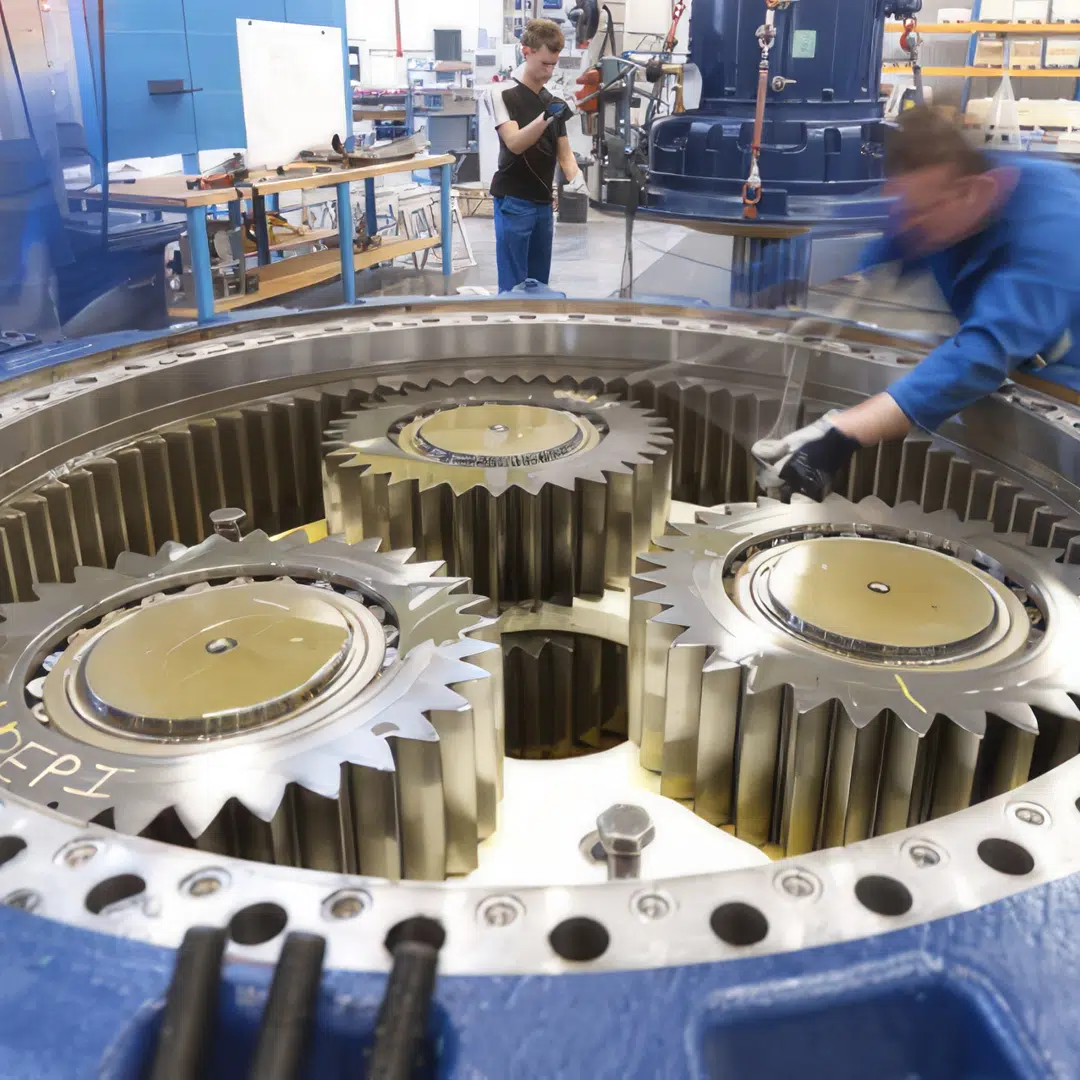

In the world of wind turbine production, gearboxes are the heart of the operation. ZF Wind Power, a leading name in the industry, knows this all too well. But even the best gearboxes can’t perform their magic if they’re not spotless. That’s where DST-CHEMICALS comes into play, with their innovative cleaning solution – DST-PINK GEL. But you may ask, why pink?

Back in 2018, DST-CHEMICALS and ZF Wind Power put their heads together to develop, test, and optimise DST-PINK GEL. The journey wasn’t without its challenges, but the result was worth every effort.

Jean-Pierre Huyberechts (ZF Wind Power): “ZF is dedicated to standardising all our fluids to a consistently high level of quality. This ensures we deliver the same top-notch results to our customers, every time, no matter whether the gearbox is produced in the US, China, India, or Belgium. That’s precisely why DST-CHEMICALS is such a crucial partner for us.”

Tackling the issue of poor wash quality

ZF Wind Power faced daily problems with poor wash quality and poor wash results using a different detergent. The gearboxes weren’t as clean as they needed to be, which led to excessive manual cleaning. Given their long-standing partnership and successful product development history, ZF Wind Power reached out to DST-CHEMICALS. Could they help develop a new cleaner?

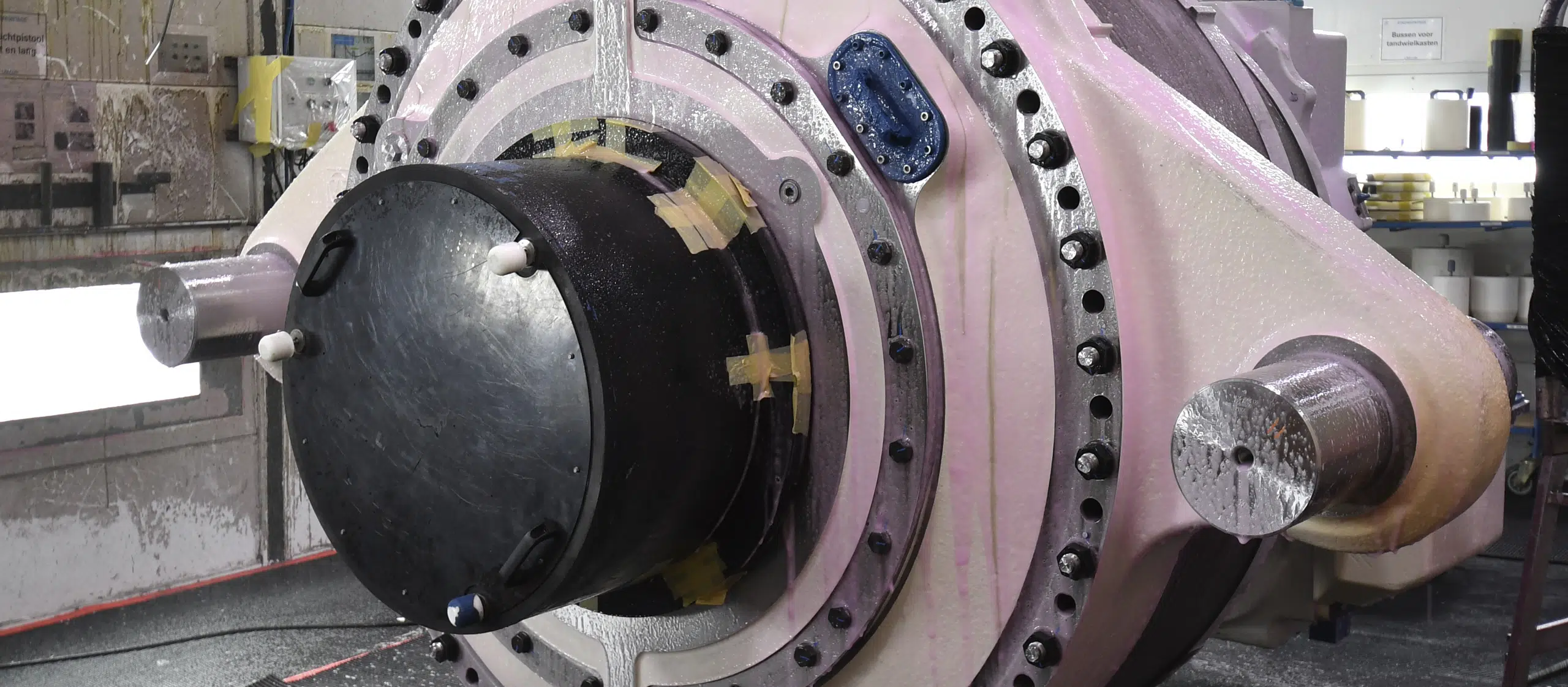

DST-PINK GEL is a ready-to-use product that’s sprayed onto the part needing cleaning, then rinsed off. Any part of the gearbox still showing the pink colour are the tricky spots that need a bit of extra elbow grease. When ZF Wind Power produces gearboxes, every part must be immaculate before moving forward to the next step in the production process.

So, next time you see a wind turbine spinning gracefully in the breeze, remember – it’s not just about the wind. It’s also about the perfect cleanliness of each gearbox, thanks to DST-PINK GEL. And yes, it’s pink for a reason!

Ready-to-use and easy to remove

ZF Wind Power had a very particular set of requirements for the new detergent. It had to be effective and versatile and yet extremely user-friendly. Enter DST-CHEMICALS, with their can-do attitude and cleaning expertise.

Through a series of rigorous tests in both Lommel (Belgium) and Kolding (the headquarters of DST-CHEMICALS in Denmark), they hit upon the perfect solution. They added a dash of pink to the detergent. Not just for aesthetics, mind you, but to help the staff identify which areas needed a bit more elbow grease. The product also had to be ready-to-use and easily applied and removed.

After studying the product’s composition, our scientists at the lab at DST-CHEMICALS found just the right solution. DST-PINK GEL was then developed, tested in various processes, and put to work – first in Lommel, Belgium, and now globally at ZF Wind Power.

More gearboxes, fewer hassles

Here’s where things get really interesting. DST-PINK GEL is applied using a hand sprayer, and after a quick 10-15 minutes, it can be effortlessly removed by one person. They then apply a water-based corrosion inhibitor DST-PAS/1.

Now, instead of spending three hours on one gearbox and taking up valuable space, ZF Wind Power can handle six gearboxes at once. And all this with just one person and without using any solvents.

Key outcome

- Co-creation and innovative solutions.

- Total cleaning and degreasing of metal parts on wind turbine gearboxes.

- Preparation for additional processing – lacquer or paint.

- Water based solution – no solvents used.

- Saves resources – both manpower and time.

- Standardising fluids – and quality – globally.